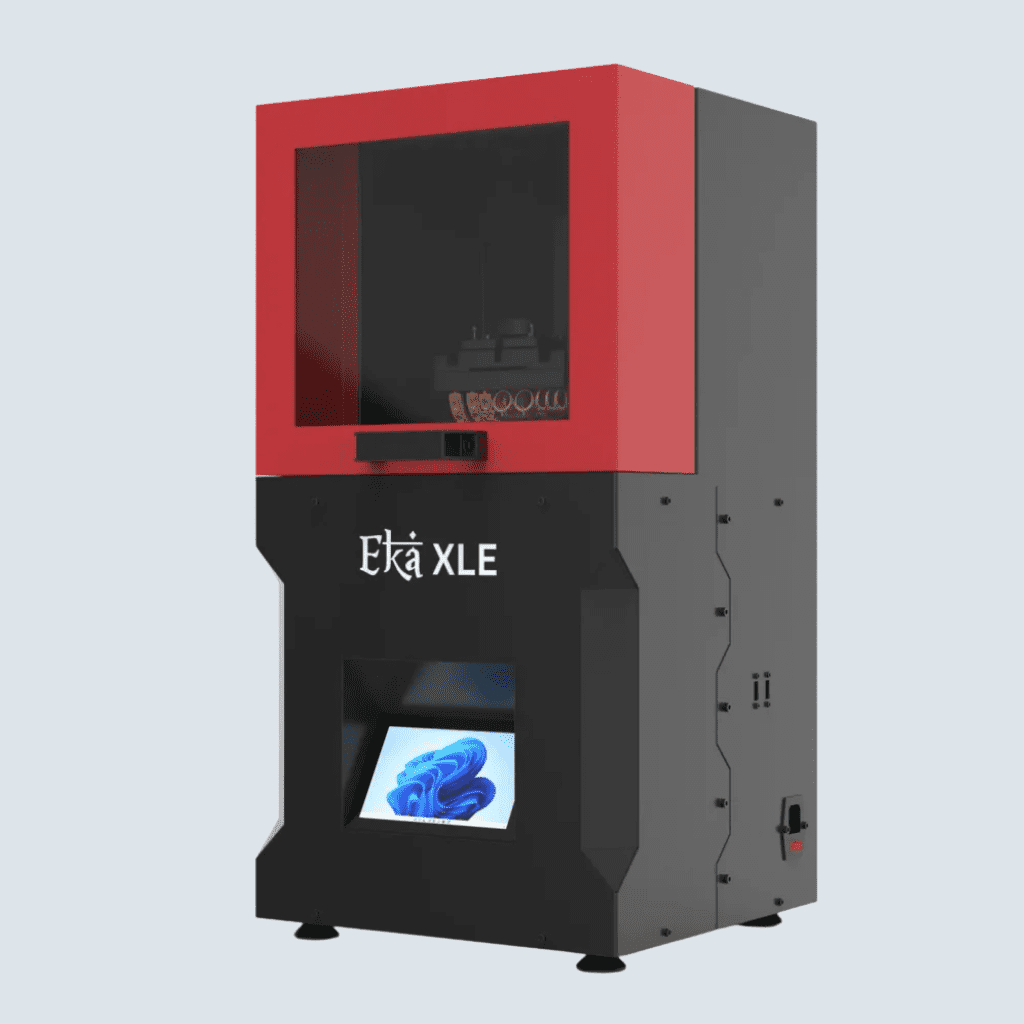

EKA XLE

The ultimate 4K Monochrome LCD 3D printer for high-precision jewelry casting, dental modeling, and complex engineering parts. Experience the speed of resin 3D printing.

Precision Stereolithography

Why professionals choose the EKA XLE for intricate manufacturing.

4K Monochrome LCD

Equipped with an industrial 4K mono screen that lasts 4X longer than standard RGB screens and delivers exceptionally sharp details.

Ultra Fast Printing

Achieve printing speeds of up to 60mm/hr with rapid layer curing times of 1.5-2 seconds, boosting your production efficiency.

Dual Linear Rails

Supported by a robust Z-axis with dual linear rails to eliminate wobbling and ensure smooth surface finishes on every print.

ParaLED Matrix

Advanced UV LED matrix provides >90% light uniformity across the entire build plate, ensuring consistent accuracy from edge to edge.

Open Material System

Compatible with a wide range of 405nm UV resins, including castable wax, dental models, tough engineering, and flexible resins.

Made in India

Designed and manufactured in India by Altmatrix, guaranteeing local support, readily available consumables, and expert training.

Master Your Craft

From casting jewelry to dental aligners, EKA XLE delivers microscopic detail.

Jewelry Casting

Direct casting patterns with zero ash content and intricate filigree details.

Dental Applications

High accuracy surgical guides, aligner models, and crowns.

Gaming Miniatures

Print incredibly detailed figurines and collectibles with smooth surfaces.

Technical Specifications

The EKA XLE sets a new standard for affordable industrial resin printing, combining speed, resolution, and reliability in one compact machine.

- Technology: MSLA / LCD

- Light Source: 405nm ParaLED Matrix

- XY Resolution: 35 Microns

- Z Axis: Dual Linear Rails

- Touchscreen Interface: 3.5" Color

- Slicer: ChituBox / Lychee Supported

- Connectivity: USB / Ethernet

- Cooling: Dual Fan Active Cooling

| Category | Specification |

|---|---|

| Build Volume | 192 × 120 × 200 mm |

| Layer Height | 0.01 - 0.15 mm |

| Printing Speed | 30-50 mm/hour |

| LCD Screen | 8.9" 4K Monochrome |

| UV Wavelength | 405 nm |

| Connectivity | USB Stick |

| Power | 120W |

| Machine Size | 320 × 300 × 500 mm |

| Weight | ~14 Kg |

EKA XLE Advantage

How EKA XLE outperforms standard RGB resin printers.

| Feature | Standard RGB Printer | EKA XLE (Mono) |

|---|---|---|

| Layer Cure Time | 6 - 8 Seconds | 1.5 - 2 Seconds |

| Screen Lifespan | ~500 Hours | ~2000 Hours |

| Light Source | Single UV LED | ParaLED Matrix UV |

| Z-Axis Stability | Single Rail | Dual Linear Rails |

| Detail Level | Standard HD | 4K Ultra Precision |

| Support | Online Only | Local Indian Support |

Trusted by Jewelers & Dentists

Over 1,000 jewelry manufacturers and dental labs across India rely on Altmatrix resin printers for their daily production needs.

- High ROI: Fast payback period due to increased production speed.

- Material Freedom: Not locked into proprietary expensive resins.

- Local Ecosystem: Easy access to spare screens, FEP films, and service.

- Expert Training: We teach you the workflow from slicing to post-processing.

Frequently Asked Questions

Is this printer suitable for Jewelry casting?

+Yes, absolutely. The EKA XLE is specifically tuned for castable resins. It prints with high detail which is crucial for setting stones and filigree work, and the parts burn out cleanly for direct casting.

What resins can I use?

+The EKA XLE is an open material system. You can use any 405nm UV resin available in the market. We also provide our own range of calibrated resins for Dental, Casting, and Tough applications.

How often do I need to change the LCD screen?

+The Monochrome LCD in the EKA XLE has a lifespan of approximately 2000 printing hours, which is significantly longer than older RGB screens. Replacement is easy and affordable through our service centers.

Does it come with slicing software?

+Yes, the printer is compatible with popular slicers like ChituBox and Lychee Slicer. We provide configuration files to get you started immediately with optimized settings.

Is post-processing required?

+Yes, like all resin printers, the parts need to be washed in IPA (Isopropyl Alcohol) and cured under UV light after printing. We offer washing and curing stations as optional accessories.

Upgrade to Industrial Resin Printing

Contact our application engineers to request a sample print or get a custom quote for your business.